Add: #11, 18F, No.171, Road Luxun, Dalian, China.

Tel: +86-411-82783087

+86-411-82783775

Fax: +86-411-82783297

E-mail: info@sino-valve.com

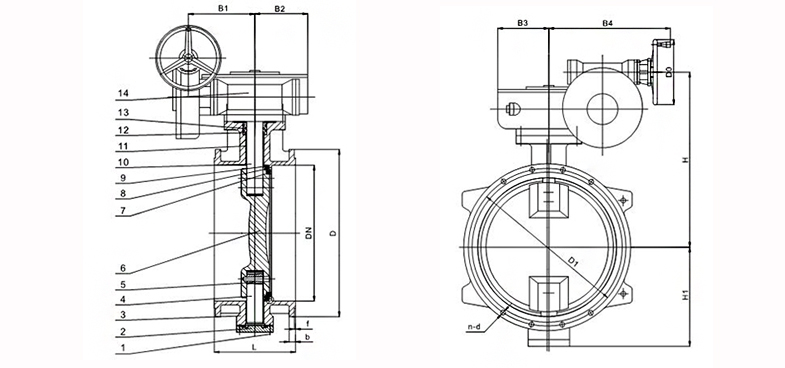

Technical Specifications of Flanged Double Eccentric Butterfly Valve:

- Design and manufacture: EN593, EN1074-1 and 2

- Face to face dimension: EN 558-1 Series 14 (DIN3202 F4)

EN 558-1 Series 13 (BS5163)

- Flange dimensions and drilling: EN1092-2 PN10/16/25

- Size range: DN150 - DN2000

- Max. working pressure: 1.0/1.6/2.5 Mpa

- Inspection test: EN12266

- Working temperature: -15°C to +80°C

- Suitable medium: water

Main Features of Flanged Double Eccentric Butterfly Valve:

- Double eccentric disc reduces seal wear and torque

- Body seat ring is welded directly on the body

- Bi-directional flow and low head loss

- Disc sealing ring to be replaceable on pipeline without dismantling the valve

- Body and disc inside and outside epoxy powder coated (min.250 microns)

- Opening and closing indicators are provided

- Coupling flange for electric actuator in compliance with ISO5211

- Gearbox and electric actuator operation available

Parts and Materials of Flanged Double Eccentric Butterfly Valve:

No. |

Parts |

Materials |

1 |

Bolt |

Stainless steel AISI 304 |

2 |

End cover |

Ductile iron EN GJS 500-7/400-15 |

3 |

Body |

Ductile iron EN GJS 500-7/400-15 |

4 |

Shaft (2) |

Stainless steel AISI 420 |

5 |

Disc pin |

Stainless steel AISI 420 |

6 |

Disc |

Ductile iron EN GJS 500-7/400-15 |

7 |

Retaining ring |

Stainless steel AISI304 or ductile iron |

8 |

Disc sealing ring |

EPDM |

9 |

Body seat ring |

Stainless steel AISI 304 |

10 |

Shaft (1) |

Stainless steel AISI 420 |

11 |

Shaft bearing |

Du bushes (self lubricating bushes) |

12 |

Shaft bush |

Gunmetal |

13 |

O-ring |

EPDM |

14 |

Gearbox |

Ductile iron |

Dimensions (mm) and weight (kgs) of Flanged Double Eccentric Butterfly Valve:

DN |

PN |

L |

D |

D1 |

b |

f |

H1 |

H |

B1 |

B2 |

B3 |

B4 |

Do |

n-d |

Closing torque (N.m.) |

Turns No. on/off |

Weight (kg) |

|

Series 14 |

Series 13 |

|||||||||||||||||

150 |

10 |

210 |

140 |

285 |

240 |

19 |

3 |

177 |

241 |

77 |

48 |

68 |

257 |

160 |

8-23 |

13.6 |

10 |

55 |

16 |

210 |

140 |

285 |

240 |

19 |

3 |

177 |

259 |

125 |

48 |

68 |

257 |

160 |

8-23 |

19.2 |

10 |

60 |

|

25 |

210 |

140 |

300 |

250 |

20 |

3 |

177 |

259 |

125 |

87 |

105 |

320 |

320 |

8-28 |

25 |

10 |

70 |

|

200 |

10 |

230 |

152 |

340 |

295 |

20 |

3 |

193 |

266 |

125 |

87 |

105 |

320 |

320 |

8-23 |

10.2 |

10 |

76 |

16 |

230 |

152 |

340 |

295 |

20 |

3 |

193 |

266 |

125 |

87 |

105 |

320 |

320 |

12-23 |

25 |

10 |

76 |

|

25 |

230 |

152 |

360 |

310 |

22 |

3 |

197 |

275 |

125 |

87 |

105 |

320 |

320 |

12-28 |

35 |

15 |

86 |

|

250 |

10 |

250 |

165 |

395 |

350 |

22 |

3 |

226 |

305 |

125 |

87 |

105 |

320 |

320 |

12-23 |

13.6 |

10 |

106 |

16 |

250 |

165 |

405 |

355 |

22 |

3 |

226 |

305 |

125 |

87 |

105 |

320 |

320 |

12-28 |

31 |

15 |

110 |

|

25 |

250 |

165 |

425 |

370 |

24.5 |

3 |

236 |

315 |

125 |

87 |

105 |

320 |

320 |

12-28 |

43.6 |

15 |

115 |

|

300 |

10 |

270 |

178 |

445 |

400 |

24.5 |

4 |

377 |

349 |

125 |

87 |

105 |

320 |

320 |

12-23 |

22.7 |

15 |

120 |

16 |

270 |

178 |

460 |

410 |

24.5 |

4 |

377 |

349 |

125 |

87 |

105 |

320 |

320 |

12-28 |

37.2 |

15 |

145 |

|

25 |

270 |

178 |

485 |

430 |

27.5 |

4 |

290 |

380 |

125 |

87 |

105 |

320 |

320 |

16-31 |

77.4 |

15 |

169 |

|

350 |

10 |

290 |

190 |

505 |

460 |

24.5 |

4 |

319 |

382 |

125 |

87 |

105 |

320 |

320 |

16-23 |

32.5 |

15 |

166 |

16 |

290 |

190 |

520 |

470 |

26.5 |

4 |

319 |

395 |

125 |

87 |

105 |

320 |

320 |

16-28 |

57.2 |

15 |

180 |

|

25 |

290 |

190 |

555 |

490 |

30 |

4 |

330 |

418 |

190 |

126 |

133 |

435 |

360 |

16-34 |

61 |

15 |

203 |

|

400 |

10 |

310 |

216 |

565 |

515 |

24.5 |

4 |

322 |

415 |

182 |

140 |

152 |

349 |

320 |

16-28 |

50 |

15 |

205 |

16 |

310 |

216 |

580 |

525 |

28 |

4 |

322 |

415 |

190 |

126 |

133 |

435 |

360 |

16-31 |

50 |

75 |

210 |

|

25 |

310 |

216 |

620 |

550 |

32 |

4 |

333 |

428 |

190 |

146 |

173 |

505 |

400 |

16-37 |

50 |

75 |

290 |

|

450 |

10 |

330 |

222 |

615 |

565 |

25.5 |

4 |

382 |

519 |

190 |

126 |

133 |

435 |

360 |

20-28 |

61 |

75 |

262 |

16 |

330 |

222 |

640 |

585 |

30 |

4 |

382 |

519 |

190 |

126 |

133 |

435 |

360 |

20-31 |

59.6 |

75 |

277 |

|

25 |

330 |

222 |

670 |

600 |

34.5 |

4 |

405 |

457 |

190 |

146 |

173 |

505 |

400 |

20-37 |

65 |

75 |

356 |

|

500 |

10 |

350 |

229 |

670 |

620 |

26.5 |

4 |

385 |

482 |

190 |

126 |

133 |

435 |

360 |

20-28 |

52.8 |

75 |

352 |

16 |

350 |

229 |

715 |

650 |

31.5 |

4 |

385 |

482 |

190 |

146 |

173 |

505 |

400 |

20-34 |

49 |

75 |

360 |

|

25 |

350 |

229 |

730 |

660 |

36.5 |

4 |

400 |

505 |

190 |

146 |

173 |

505 |

400 |

20-37 |

50 |

135 |

485 |

|

600 |

10 |

390 |

267 |

780 |

725 |

30 |

5 |

465 |

554 |

216 |

183 |

212 |

512 |

450 |

20-31 |

48 |

75 |

558 |

16 |

390 |

267 |

840 |

770 |

36 |

5 |

465 |

554 |

190 |

146 |

173 |

505 |

400 |

20-37 |

45.5 |

135 |

566 |

|

25 |

390 |

267 |

845 |

770 |

42 |

5 |

476 |

578 |

216 |

183 |

212 |

512 |

450 |

20-40 |

68 |

135 |

580 |

|

700 |

10 |

430 |

292 |

895 |

840 |

32.5 |

5 |

550 |

630 |

216 |

183 |

212 |

512 |

450 |

24-31 |

41 |

135 |

691 |

16 |

430 |

292 |

910 |

840 |

39.5 |

5 |

550 |

625 |

216 |

183 |

212 |

512 |

450 |

24-37 |

68 |

135 |

745 |

|

25 |

430 |

292 |

960 |

875 |

46.5 |

5 |

590 |

665 |

258 |

253 |

283 |

563 |

500 |

24-43 |

75 |

255 |

842 |

|

800 |

10 |

470 |

318 |

1015 |

950 |

35 |

5 |

590 |

678 |

216 |

183 |

212 |

512 |

450 |

24-34 |

54 |

135 |

863 |

16 |

470 |

318 |

1025 |

950 |

43 |

5 |

590 |

678 |

216 |

183 |

212 |

512 |

450 |

24-40 |

85.4 |

255 |

875 |

|

25 |

470 |

318 |

1085 |

990 |

51 |

5 |

630 |

816 |

287 |

265 |

302 |

626 |

500 |

24-49 |

66 |

412.5 |

1210 |

|

900 |

10 |

510 |

330 |

1115 |

1050 |

37.5 |

5 |

640 |

838 |

216 |

183 |

212 |

512 |

450 |

28-34 |

73 |

255 |

1080 |

16 |

510 |

330 |

1125 |

1050 |

46.5 |

5 |

640 |

838 |

258 |

253 |

283 |

563 |

500 |

28-40 |

75.4 |

255 |

1190 |

|

25 |

510 |

330 |

1185 |

1090 |

55.5 |

5 |

685 |

688 |

287 |

265 |

302 |

626 |

500 |

28-49 |

90 |

412.5 |

1620 |

|

1000 |

10 |

550 |

410 |

1230 |

1160 |

40 |

5 |

720 |

925 |

258 |

253 |

283 |

563 |

500 |

28-37 |

68 |

255 |

1750 |

16 |

550 |

410 |

1255 |

1170 |

50 |

5 |

720 |

925 |

258 |

253 |

283 |

563 |

500 |

28-43 |

98 |

255 |

1880 |

|

25 |

550 |

410 |

1320 |

1210 |

60 |

5 |

770 |

1030 |

287 |

265 |

302 |

626 |

500 |

28-56 |

90 |

600 |

2130 |

|

1200 |

10 |

630 |

470 |

1455 |

1380 |

45 |

5 |

895 |

1127 |

287 |

265 |

302 |

626 |

500 |

32-40 |

73 |

412.5 |

2313 |

16 |

630 |

470 |

1485 |

1390 |

57 |

5 |

895 |

1127 |

287 |

265 |

302 |

626 |

500 |

32-49 |

98 |

412.5 |

2330 |

|

25 |

630 |

470 |

1530 |

1420 |

69 |

5 |

940 |

1245 |

287 |

265 |

302 |

626 |

500 |

32-56 |

98 |

600 |

2620 |

|

1400 |

10 |

710 |

530 |

1675 |

1590 |

46 |

5 |

985 |

1280 |

287 |

265 |

302 |

626 |

500 |

36-43 |

98 |

412.5 |

3456 |

16 |

710 |

530 |

1685 |

1590 |

60 |

5 |

985 |

1327 |

352 |

365 |

330 |

670 |

640 |

36-49 |

98 |

600 |

3510 |

|

25 |

710 |

530 |

1755 |

1640 |

74 |

5 |

1010 |

1025 |

352 |

365 |

330 |

778 |

500 |

36-62 |

90 |

600 |

3870 |

|

1500 |

10 |

750 |

560 |

1785 |

1700 |

47.5 |

5 |

1010 |

1348 |

352 |

365 |

330 |

670 |

640 |

36-44 |

98 |

600 |

2980 |

16 |

750 |

560 |

1820 |

1710 |

62.5 |

5 |

1040 |

1370 |

352 |

365 |

330 |

670 |

640 |

36-57 |

98 |

600 |

3870 |

|

25 |

750 |

560 |

1865 |

1750 |

77.5 |

5 |

1082 |

1100 |

352 |

365 |

330 |

778 |

500 |

36-62 |

100 |

600 |

4980 |

|

1600 |

10 |

790 |

600 |

1915 |

1820 |

49 |

5 |

1100 |

1420 |

287 |

265 |

302 |

626 |

500 |

40-50 |

98 |

600 |

5162 |

16 |

790 |

600 |

1930 |

1820 |

65 |

5 |

1110 |

1427 |

287 |

265 |

302 |

626 |

500 |

40-57 |

100 |

600 |

5800 |

|

25 |

790 |

600 |

1975 |

1860 |

81 |

5 |

1145 |

1175 |

352 |

365 |

330 |

778 |

500 |

40-62 |

100 |

1500 |

6780 |

|

1800 |

10 |

870 |

670 |

2115 |

2020 |

52 |

5 |

1198 |

1234 |

352 |

365 |

330 |

778 |

500 |

44-50 |

90 |

1200 |

5400 |

16 |

870 |

670 |

2130 |

2020 |

70 |

5 |

1203 |

1260 |

352 |

365 |

330 |

788 |

500 |

44-57 |

91 |

1500 |

5916 |

|

25 |

870 |

670 |

2195 |

2070 |

88 |

5 |

1290 |

1300 |

352 |

365 |

330 |

788 |

500 |

44-70 |

130 |

1500 |

7280 |

|

2000 |

10 |

950 |

760 |

2325 |

2230 |

55 |

5 |

1347 |

1360 |

352 |

365 |

330 |

778 |

500 |

48-50 |

100 |

1200 |

8860 |

16 |

950 |

760 |

2345 |

2230 |

75 |

5 |

1420 |

1430 |

352 |

365 |

330 |

788 |

500 |

48-62 |

100 |

1500 |

10900 |

|

25 |

950 |

760 |

2425 |

2300 |

95 |

5 |

1460 |

1500 |

352 |

365 |

330 |

788 |

500 |

48-70 |

180 |

1500 |

13800 |

|

Copyright@2017 Dalian Dawei International Co., Ltd. All Rights Reserved.